Processes

During this section i have decided to go onto look at the actual printing process itself, there are many types of process all of them achieving different attributes, by generating this research i feel this will aid me in that i will always be able to look back and see what process will be most suitable and effective for the job on hand. As you can see i have highlighted the information that i feel is of most importance and that will help me when deciding on what print process to use.

Lithographic

Information has been sourced from:

www.facemediagroup.co.uk

The name lithography comes from lithos, stone, and graphia and was invented in Prague byAlois Senefelder around 1796. Lithography is best described as a planographic process; this is nothing more than a process for printing from a smooth surface, called a plate, to a substrate, generally paper.

In Mr. Senefelder's day lithography transferred the ink directly from the stone or plate to the substrate. Today lithography is generally called Offset or Offset Lithography; both of these terms refer to the same process. In this printing process, offset lithography, the image to be printed is rendered or etched onto a flat surface, (the plane) such as a sheet of aluminum, plastic, or zinc. Next the image is transferred to a rubber roller, and then finally to the substrate.

How does Lithographic printing work?

How does this work you may be wondering. Well the process is simple and it is based on the elementary principle that oil and water do not mix. There are a few steps in converting your image/text into a printed page so let us discuss the plates first.

In lithography the plates have a roughened texture and are coated with a photosensitive (light sensitive) emulsion. This emulsion is a suspension of two chemicals that cannot be mixed together, a common household example of an emulsion is butter or margarine.

Plates are made one of two ways: Exposure from light source with film on top of the plate, or using a machine that exposes the plate, using lasers directly from the computer. Either way creates a photographic negative of the desired image, releases the emulsion, and transfers a positive image to the emulsion. The emulsion is then chemically treated to remove the unexposed portions of the emulsion. This final step is similar to developing film at a photo lab.

When the printing plate is made, the printing image is rendered grease receptive and hydrophobic, or water repelling. The non-printing areas are rendered hydrophilic, or water attracting, and ink repelling. On the press the plate is mounted on the plate cylinder which as it rotates, comes into contact first with the rollers wet by a dampening solution or water, which adheres to the rough, or negative portions of the image. Then the plate comes in contact with the roller coated with ink, which adheres to the smooth, or positive portions of the image.

If this image were directly transferred to paper, it would create a positive image, but the paper would be moistened. Instead, a cylinder covered with a rubber surface, called a blanket, is rolled over the plate. The blanket squeezes away the water, and picks up the ink. The cylinder is then rolled over the paper, transferring the ink. Because the image is first transferred to the blanket cylinder, we call this process “offset lithography” because the image is offset to the drum before being applied to the paper.

The Advantages of Lithographic Printing

One major advantage of the lithography is that the soft rubber surface of the blanket creates a clear impression on a wide variety of paper surfaces and materials. Lithography printing is easily recognized by its smooth print, as well as by the lack on any impression or ring of ink or serrated edges that are characteristic of letterpress or gravure printing.

Lithography has equipment for short, medium, and long press runs. Sheet-fed and web presses are both used in lithography. Sheet-fed lithography is used for printing advertising, books, catalogs, greeting cards, posters, packaging, direct mail inserts, coupons, and art reproduction.

Many sheet-fed lithography presses can ‘perfect’, print on both sides of the paper, in one pass through the press. Web lithography is used for newspapers, preprinted newspaper inserts, advertising literature, catalogs, books, and magazines.

Lithography has equipment for short, medium, and long press runs. Sheet-fed and web presses are both used in lithography. Sheet-fed lithography is used for printing advertising, books, catalogs, greeting cards, posters, packaging, direct mail inserts, coupons, and art reproduction.

Many sheet-fed lithography presses can ‘perfect’, print on both sides of the paper, in one pass through the press. Web lithography is used for newspapers, preprinted newspaper inserts, advertising literature, catalogs, books, and magazines.

Gravure:

The Gravure process is a type of intaglio process in which the actual image is etched into the surface of a plate or metal cylinder. The image consists of tiny cells (or wells) engraved into the cylinder; there may be as many as 22,500 ink wells per square inch. When the cylinder is rotated in a fountain of ink, the excess ink in the non-image area is removed by a thin piece of stainless steel called a doctor blade. The size and depth of each ink well determines how much ink will be deposited on the substrate. When paper is passed between the plate cylinder and rubber impression roller, it acts like a blotter and absorbs the remaining ink in the microscopic wells.

In gravure printing there are sheetfed and webfed (rotogravure) presses. Sheetfed gravure is targeted at limited production runs of fine art prints, high quality art, photographic books, advertising leaflets, and higher denomination postage stamps. Rotogravure is targeted at larger runs of 300,000 copies or more and includes weekly or monthly magazines, mail order catalogs, specialized packaging, wallpaper, and some decorative laminates. Both presses require plate-making (or cylinder engraving) and proofing, which is often very expensive. Color corrections and last-minute changes often require cylinder retouching, and this can sometimes be slow and very time-consuming.

Screen print

Method in which ink is applied directly to the surface to be printed (substrate). The image to be printed is photographically transferred to a very fine fabric (the screen) such that the non-printing areas are blocked off and the fabric serves as a stencil. The ink is wiped across the screen to pass through the unblocked pores and reach the substrate. For each colour to be printed a separate screen is prepared and the process is repeated.

Screen printing is a low volume printing method where viscous ink is passed through a screen this was origionally made with silk, that holds a design onto a substrate. Although a relatively slow low volume and very expensive printing method. This method allows the designer to apply images to a range of different substrates. the effect of screen print gives the design texture this gives the design a handmade identity and this allows the viewer to interact with the print much more makes it feel personal.

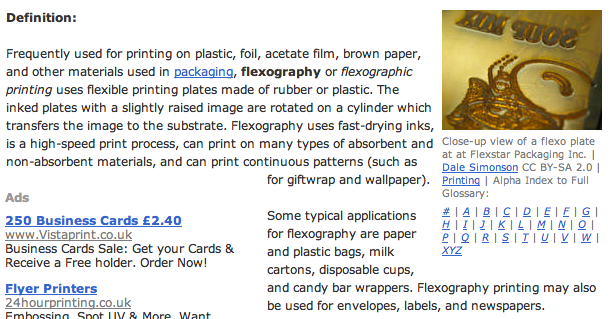

Flexography

This technique is frequently used for printing onto plastics, foils, acetate, brown papers and basically any other materials that are used within packaging, Flexography or Flexographic printing uses a method where printing plates that are made of rubber or plastic are inked with a slightly raised image are rotated onto a cylinder which then transfers the image to the substrate. Flexography uses very fast drying inks, as it is a very high speed print process, this process is capable of printing on s range of absorbent and non absorbent material. commonly used for printing a continuous pattern such as wrapping paper and gift wrap.

Some typical applications for flexography are paper and plastic bags, milk cartons, disposable cups, sweet wrappers. Flexographic printing can also be used, to print envelopes, labels and newspapers.

Pad printing

The image that is being printed is etched into a plate this is called the Cliche. the Cliche is commonly made of a pollymer coating on a metal backing of steel. Once this is placed onto the printer, the Cliche is inked by an open inkwell.

Ink in Pad Printing

Pad printing inks are just as versatile as the other elements within the pad printing process, they are not only s huge range of colours available but they also come in a range of series which are specific to the type of substrate that is being printed onto. Different materials react differently to some elements in the inks. For example the inks used for printing on certain plastics will not be the same as the inks used for printing on glass or aluminium. There are medical grade inks that can be used for the medical industry and even edable inks that can be printed onto foods.

The Pad

After the Cliche is inked up, the silicon pad then picks up the image and transfers it to the product. the pads themself are made of a silicon material that can vary on hardness. The properties of the silicon allow the inks to temporarily stick to the pad, How ever they can be fully released from the pad when it comes into contact with the product that is to be printed. The hardness of the pad dictates how the image molds to the product - For example if you where to print an image onto a basketball a harder pad would transfer more of the print into the textured surface. When printing onto a relatively flat surface the pad can be made of a softer material as less downward pressure is needed.

Information Sourced from

http://www.padprintmachinery.com/support/generalIssue.cfm?issID=15

Six colour

Hexachrome Printing

The Hexachrome system uses six colours instead of the conventional four used in traditional colour print.

By supplementing the Cyan, Magenta, Yellow and Black with Orange and Green it is possible to produce a greater range of colours accurately. The results can be a much more vibrant and high impact print.

If you are interested in printing using this system later versions of Quark Express and Coral Draw are Hexachrome enabled. Pantone® have also produced plugins for use with Adobe InDesign, adobe Illustrator and Adobe Photoshop.

Alternatively, we may be able to convert the design you have supplied to include Hexachrome colours or images.

Please note: The conversion work is chargeable. We can supply Hexachrome Colour Swatch Books from Pantone®, Solid Pantone® or specific House Colours that need to be matched to a Hexachrome equivalents.

Information sourced from:

http://www.bluepoleprint.com/faq/hexachrome

Letter press printing:

Letterpress printing

This method was originally done with moveable type. It is a form of relief printing – where the parts to be printed, both type and illustrations, are raised up from the base plate. It is commonly used for small printing jobs such as business cards and stationery. Illustrations for letterpress printing are made by a photographic process. Types of letterpress printing machines are:

- Platen press The paper is pressed against the printing plate by a flat piece of metal called a platen. The plate is inked by rollers as the platen is opened.

- Sheet-fed rotary press These have a curved printing surface and can print single sheets at a high speed.

- Flat sheets are fed between the plate and a pressure roller.

- Flat-cylinder press The printing plate is flat and paper is passed over it by a rotary pressure roller.

Letterpress printing is not often used now, as it is time-consuming to set up the loose type and make the plates, and there is only a limited range of fonts and styles.

Laminate gloss and matt

Lamination – The most common finish is a lamination. This is where a plastic film is heated onto the paper. The finish can either be a gloss, silk or matt lamination.

Spot UV varnish

- UV Varnish – This is a cheaper alternative to lamination, and is a varnish rather than a film, and gives a high gloss finish.

- Spot uv varnish – This is where perhaps pictures or images are picked out in gloss or matt uv.

No comments:

Post a Comment